My first job in Australia would be as a tractor driver for The Great Australian Grape Harvest. After my Outbackpackers experience, I was shipped to South Australia just south of the Barossa Valley wine region.

Harvesting

I suppose you’re just dying to know all about the grape harvest. How do they get that succulent bottle of red or white wine from all those little grapes?

Well, to be clear, I covered the harvesting, not the crushing, etc. (See below) My job, however, was to drive the bin beside the grape harvester that would collect the grapes shaken from the vines.

Let me introduce you to the Grape Harvester.

A grand, fearsome-looking machine, it actually reminded me of Pac-Man: it would gobble a vine row and beat it to a purply pulp as it shook the grapes (and twigs, snakes and fruit spiders) off of the vines leaving nothing but a battered and bruised grape vine behind. The grapes would then make their way through a series of conveyors and be deposited into a bin one row over (my job was to navigate the bin.)

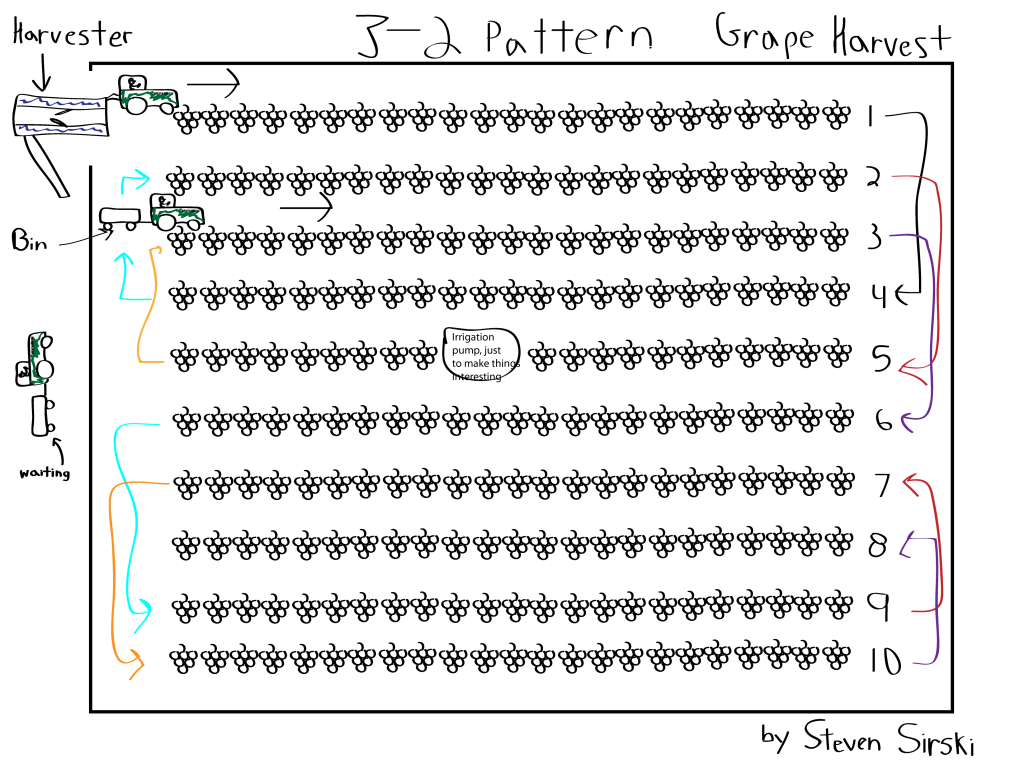

The most confusing thing for me was knowing and understanding the picking pattern. Since the harvester straddles the vines, the machine takes up about two rows of vines. As a result, you can’t do very sharp turns with the thing. Sure, any farmer will tell “you’ve got lots of room” and you do, if you’ve done it before. If you haven’t, well, some fencing might need to be done afterward. If any of you are considering working the grape harvest, you’d be wise to study some of the picking patterns. The two patterns we used most was the 3/2 and the 4/3, though we did use the 7/6 pattern one or two times. WTF is all that?

Go in four, go back three, go in four, go back three, go in four, trace back three and now you have a completed pattern. Same same the 7/6 pattern, except bigger. Below is a diagram of the 3/2 pattern for your study:

There were a few times I went down the wrong row which not only tied up production, but led to some considerable tension. Bear in mind the vineyards are packed so it’s an optimal growing space, not optimal tractor-turning space. So when you go down the wrong row you either have to keep going forward (which would then necessitate making a full lap of the vineyard) or, if messed up by only one row and thus were now BEHIND the harvest instead of simply being in the wrong row, then guess what you had to do. No, you do not wait. Time is money, literally, in the grape harvesting business. Nope, you gotta reverse that tractor, bin ‘n’ all and then get into the right row. For demonstration purposes, try it with a Power Wheels car and a wagon behind it. Same same but different.

It could get frustrating out there because of that time restraint. The reason for this is because the farmers don’t get to choose when their grapes go to the winery. Rather, the winery gives them a delivery time and the farmer must meet it. For example, if the farmer is asked for a load or a B-Double, then the load (9 bins per load or 15 bins for a B-Double) must arrive at the winery within that allotted time. Keep in mind, you need someone to drive the truck (what we call a “Semi” in Canada) to the winery, unload the bins, then bring the truck back before the next load is finished. It’s about efficiency. Although the first pick or two were a little difficult, as harvest progressed we were able to pick a load (9 bins) in about 3 hours, or about 15 minutes per bin. Each bin weighed about two tonnes.

After the bin was full, the boss urged (I use those words with some strength) me to get a move on to unload the bin, sprinkle some chemical preserver on the berries, load a new bin, and get back in the queue behind the other tractors. The job would be easier with a larger team. We started out with four or five of us (including the truckie), but by the end of harvest one guy had to pull out due to other commitments. Unfortunately, when you’ve proven you’re good at something, people expect you to do more of it faster and better. The benefit of a smaller team, however, is that those all-night picks go by like nothing: there’s no time to check your watch or contemplate your life’s decisions. You just go. That 15 minute-bin change goes by fast.

Those bin changes were marked with some frustration, to the point that one time, nearing the end of the harvest when sleep deprivation and toleration were at a low, I had a nice little conversation with the forklift and the loaded bin I was trying to remove. Lucky for me, the truckie, Salty, witnessed this little exchange and offered some assistance. The grace with which this oversized man maneuvered the forklift, gently picking up the loaded bin and replacing it with an empty one left me humbled. Sometimes it just requires a little patience and another go. Fucking forklift. If I ever meet the guy who designed it, I’d ask him just how he was planning on seeing through the machine while carrying a load.

Depending on the size of the order, we’d pick for about 12 to 26 hours. Sound like too much? Well, yes, picks can go on that long since, like all farming, the pick isn’t just determined by the order, but by the weather. If you’re expecting bad weather a farmer might choose to send his grapes to different wineries in order to accommodate such a large yield.

Here’s a short video of us finishing up The Great Australian Grape Harvest:

[youtube]https://www.youtube.com/watch?v=-a1FC6dMw00[/youtube]

After the Pick

As for after the pick, we I had to clean the tractors, bins, re-grease the harvester with some blue vegetable-oil grease stuff (don’t want synthetic oil getting into the grape juice), etc. The grape harvester itself is a neat machine but the smell of it after a pick, well, it coated the back of your throat with that misty green-coloured smell of dead stuff… such as rotting fruit. And guess whose job it was to clean it out? Mine. In total the machine had about 36 bearings to be greased, not all of which were easily accessible.

So you’re probably wondering what happens to all those grapes after they’re picked. While they’re waiting to be taken to the winery, they are preserved with a chemical substance (that’s the stuff that gives you headaches when you drink too much) before they are loaded onto a truck and taken in. Once at the winery, they are unloaded by a guy who hasn’t slept in three days (lots of hours and good money = sleep later) who delicately removes them off of the truck with the grace of a ballet dancer and lines them up in a nice and neat row. The grapes are then deposited into a massive de-stemmer which removes all of the stems, twigs and remaining insects and snakes. Then follows crushing, a couple of fermentation processes, pressing, and then more fermentation. That’s a rather simplified version of what goes on, but if you want to read more, read Wikipedia.

The wine tasted pretty damn good with both the red and white going down well. Neither left a hangover which meant we could potentially drink a few bottles not feel a thing in the morning. He told me that every year he gets a few hundred bottles made from his crop. He even had his own wine storage SHED. That’s hardcore. You could tell the guy took great pride in his crop. Lucky for me he supplied me with a few bottles at the end of harvest.

All in all, every time I buy wine I can’t help but think “I made that,” even thought I really didn’t. I did ask him when I could expect to see “my grapes” on sale and he said it would be the 2012 vintage of some of the major brands, such as Yellow Label and Lindeman’s. Not gonna lie, feeling kinda proud.

I stayed for six weeks in total on that farm before taking a “holiday” from the work force. I dropped by Melbourne to visit my “Rellies” (that’s “relatives” in Canadaspeak) before moving on to West Australia for my next job.